|

Installing the Raspberry Pi Compute

Module 5 |

|

Step 1

Protecting from ESD |

|

|

Grounding protects the

components from the static electricity that

can be naturally present (electrostatic

discharge, ESD).

|

|

|

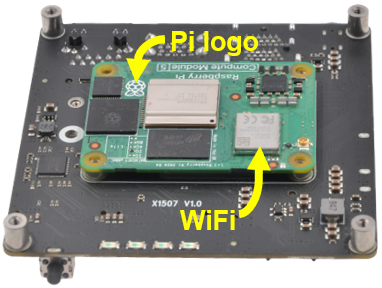

Step 2

Aligh the IO

board and CM5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

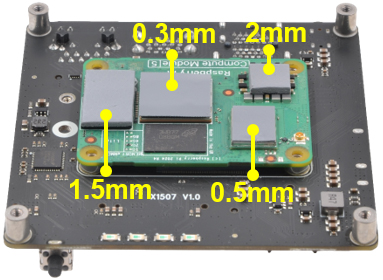

- Confirm the Compute Module

is correctly mated by looking at

each corner of the IO Board.

|

|

|

|

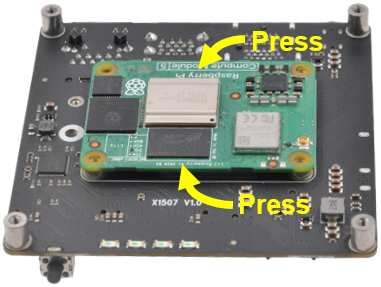

Step 3

Installing

the CM5 |

|

|

|

|

|

|

|

|

|

|

-

This

requires quite a bit of force.

If you don't hear a loud click,

it is most likely not fully

seated.

-

Do a visual

check to make sure the CM5 is

installed correctly: it needs to

run parallel to the IO board.

|

|

|

|

|

|

CAUTION!

Do not press on any chipsets, as

this may damage your CM5. |

|

|

|

Step 4

Use silicone

thermal pads for optimal heat dissipation |

|

|

|

|

|

|

|

-

Inspect

for Debris: Dust, oil,

or residue can interfere with

heat transfer, so make sure both

surfaces are spotless.

|

|

|

- RP1 and

Ethernet IC: 1.5mm (LxW, 12x20.6mm)

- CPU: 0.3mm

(LxW, 17x17mm)

- PMIC: 2mm

(LxW, 10x10mm)

- WiFi module:

0.5mm (LxW, 13x10mm)

CAUTION! Using

incorrect pad thickness may damage

your CM5.

|

|

|

|

|

|

|

|

|

|

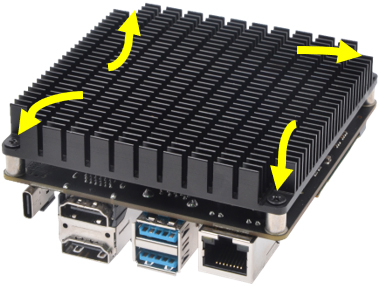

Step 5

Installing the heat sink |

|

|

|

|

|

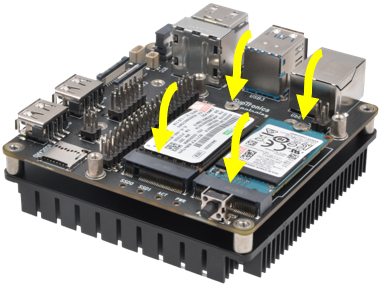

Step 6

Installing the M.2 2242 NVMe SSD devices |

|

|

|

|